While Artificial intelligence (AI) is having a moment, it’s not a flash in the pan and it’s definitely here to stay. While the advent of generative AI, like ChatGPT, has prompted concerns related to plagiarism, copyright infringements, and data privacy, not all AI technologies raise these same concerns. For example, other forms of AI are being used successfully in the fisheries tech space to modernize fisheries.

To that end, we wanted to start 2024 by highlighting some of the innovations in the fisheries tech space by companies whose work we’ve been following closely. They’re using AI for everything from enhancing data processing to driving more accurate precision fishing to reducing waste in the seafood supply chain, contributing to the industry’s evolution while playing a crucial role in fostering sustainability in our oceans.

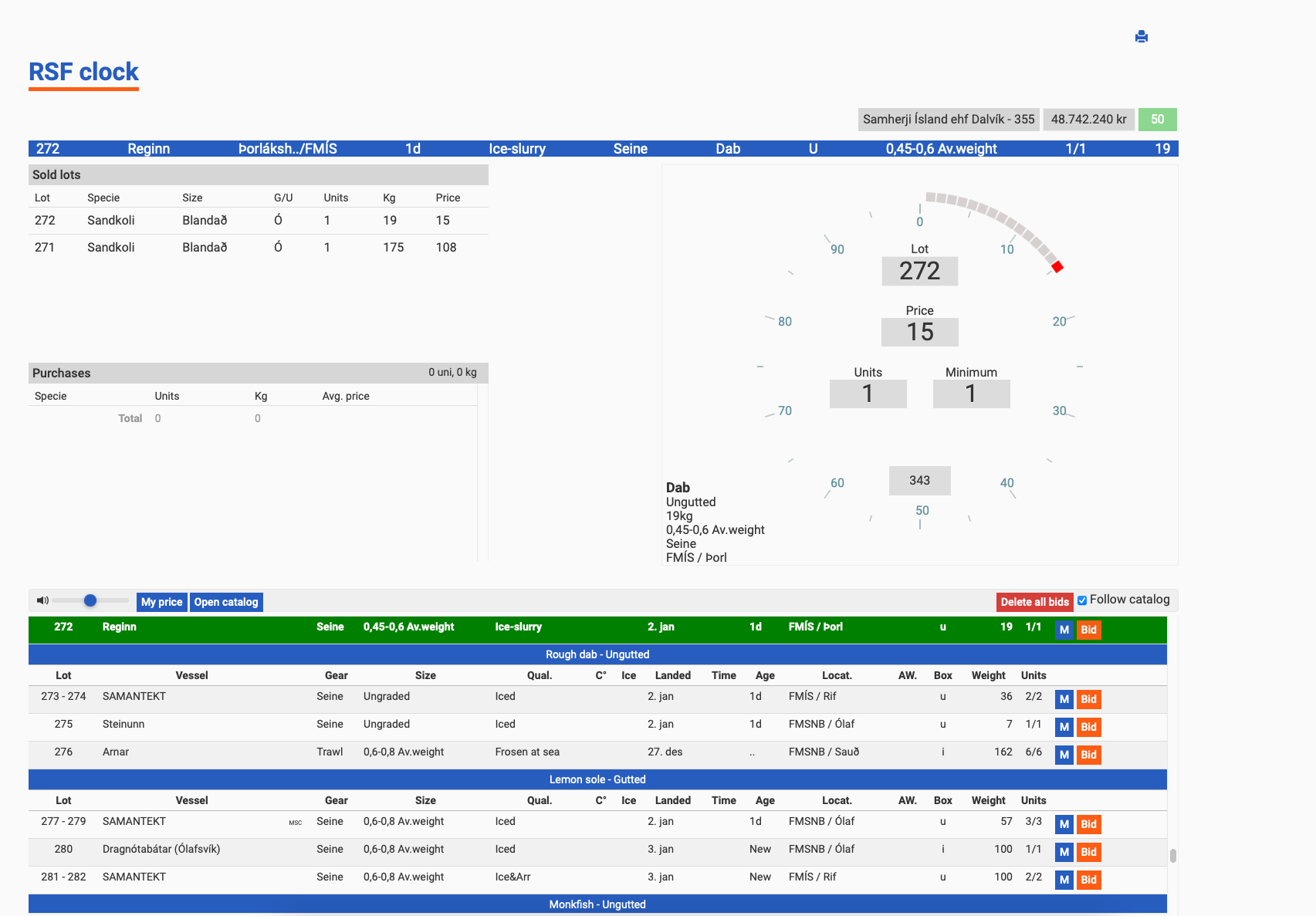

Reiknistofa fiskmarkaða RSF

Icelandic company RSF develops and delivers innovative solutions for the Icelandic seafood industry and beyond. RSF connects 11 fish auctions in 45 locations into one auction network and conducts daily auctions where 200 – 300 buyers purchase fresh fish remotely in real time. They also collect payments from buyers and disburse sellers, auctions, harbours, government, and more.

We put some questions about their technology and how they’re using AI to RSF CEO Bjarni Heimisson:

Have you integrated AI technology within RSF’s auction network operations? If so, how is it used?

We have an AI model that both learns from old prices and predicts the prices before an auction and also learns while the auction is going on and adjusts those prices according to the current auction. Our auction is a Dutch auction, ie. It counts down from a starting point until the first buyer buys/wins. So it is crucial for us to have a good starting point. The model helps us do that.

In what ways does RSF’s technology address the specific challenges involved in establishing and maintaining a robust, real-time auction network?

We try to collect as much data as possible for our prediction model. But, that can be challenging as there are often many other factors needed to predict if the price is going up and down. Sometimes, something in another country affects it and makes it hard for us to keep track. That’s why it is important to have a model that works in real-time on top of our auction network to adjust price prediction.

Do you collect big-picture data supporting sustainable practices within Iceland’s seafood industry and beyond?

Yes, we do. We mostly do it for Iceland right now, as that is our main market. However, we are working on collecting other auction feeds to improve our predictions.

SafetyNet Technologies

UK-based SafetyNet Technologies develops precision fishing tools, including LED lights, underwater video cameras and ocean sensors, to make commercial fishing more predictable, profitable and sustainable. They design their products with fishermen, for fishermen, and user feedback guides their entire product design and development process. Their CatchCam underwater camera has recently started being distributed in Canada.

We asked Dan Watson, the Co-Founder and CEO of SafetyNet Technologies, how they’re using fishing technology and AI:

How does your technology contribute to promoting sustainability within the fishing industry?

At SafetyNet Technologies, we create tools that help fishermen catch their target species more efficiently and sustainably. These tools improve our understanding of the ocean, let us observe how target and non-target species interact with fishing gear, and if selectivity devices are working properly. As a result, fishing crews can make data-driven decisions during operations to optimize their efforts and comply with regulations.

How are you integrating AI within your existing solutions and the solutions you’re developing?

We’re currently integrating computer vision and machine learning techniques into our products to accelerate the rate at which non-scientist users on fishing vessels can assimilate and learn from large amounts of ocean data to enable operational changes that create precision fishing outcomes. These techniques are under active development – and we are excited to share them later in 2024.

What methods or technologies are you employing for gathering and processing large volumes of oceanic data? Are you using AI to extract insights from this data? If so, how?

We’re actively using fishing gear as platforms to gather large amounts of subsea oceanographic and video data and are using various methods, some of which involve computer vision and machine learning techniques, to extract meaningful insights from them. We are also big proponents of “human learning” as we analyze ocean data, which forms the foundations of our machine-learning approaches. We work extensively with fishermen and scientists to guide how we gain meaning from sensor data.

ThisFish

Founded on Canada’s West Coast, ThisFish is a global leader in seafood traceability software and Artificial Intelligence that reduces costs, strengthens process control and improves compliance in supply chains. ThisFish is committed to modernizing the fishing industry and improving the social, environmental and financial sustainability of seafood.

Here’s how Eric Enno Tamm, CEO and Co-Founder of ThisFish, answered our questions about employing AI and machine learning in their work.

How do you leverage AI and machine learning to enhance data interpretation and decision-making?

Our Tally platform enables seafood producers to digitize their production, quality control, inventory, and supply chain traceability data. We’ve been researching and developing machine learning to add more value to this data. Here are some examples:

- We used traceability and production data to develop a yield prediction tool for a salmon processor and tuna cannery. Even before they cut the fish, TallyBot, our AI-enabled digital helper, predicts what the yield will be. This also allowed us to develop a raw material costing tool for the salmon processor.

- Using quality control and production data in a tuna cannery, we created a TallyBot that will predict drained weights of tuna cans. Analysis suggests that this could save a cannery more than one gram of tuna per can – and potentially hundreds of thousands of dollars.

- We’re about to start work with a live lobster exporter to understand better what is driving the mortality of live lobsters shipped overseas. For each sales order, mortality can range from a few percent to as high as 25 percent. We’re hopeful that AI can help us better understand what drives this mortality.

How does your technology contribute to sustainability in the fishing industry, particularly through AI’s role in resource management and environmental impact reduction?

We are focused on mid-supply chain actors such as processors, distributors and traders. So most of the AI that we work on is related to reducing waste in the supply chain by better matching supply and demand, reducing mortality of live products or increasing the yields so less fish is going to waste or byproducts.

We’ve also worked on AI-enabled anomaly detection to identify errors or fraudulent behaviour in supply chains, aiding in traceability data validation.

Looking beyond AI, how do you envision technologies like IoT and blockchain shaping the future of commercial fisheries, and how does your company plan to integrate them?

Data is often called the new “oil” in the Information Age, which is fueling the growth of AI. Indeed, data quality and quantity are key to enabling AI to learn. Therefore, we can use IoT (Internet of Things) sensors to automatically collect data, reducing the cost of collection and improving the quality since we are removing human error and bias. So, IoT sensors are going to play a huge role in enabling and expanding AI in the future in seafood.

We’ve incorporated a cutting-edge, wireless temperature sensor into our Tally platform since cold chain monitoring is necessary for many of our customers. We’ve also integrated a smart camera into TallyVision, a new product that enables continuous, automated inspection in seafood factories. Instead of quality control done manually using random samples evaluated by people, TallyVision uses neural networks and computer vision algorithms to automatically classify fish or filets by size, colour and defects, removing human error and bias from inspection while also inspecting 100% of products. It’s also a great example of how AI is exponentially increasing the quantity of data while improving data quality.

These examples merely scratch the surface of how AI is transforming fishing technology and modernizing the seafood industry. Beyond their immediate impact, these innovations also play a crucial role in broader industry goals for environmental conservation and responsible resource management. We’d love to know how your company uses AI, drop us a line and let us know as we may expand this series throughout 2024 and showcase other industry innovations.